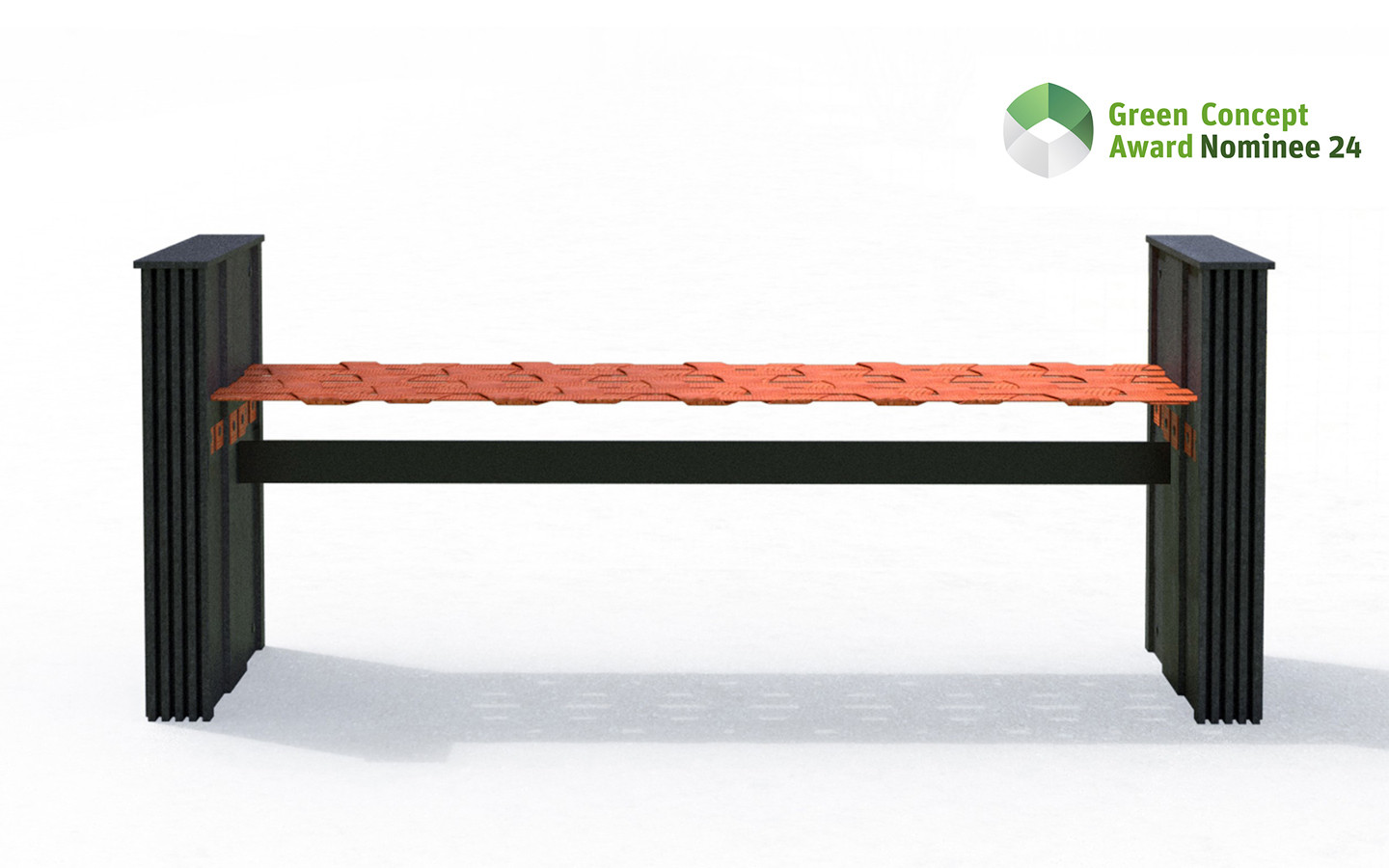

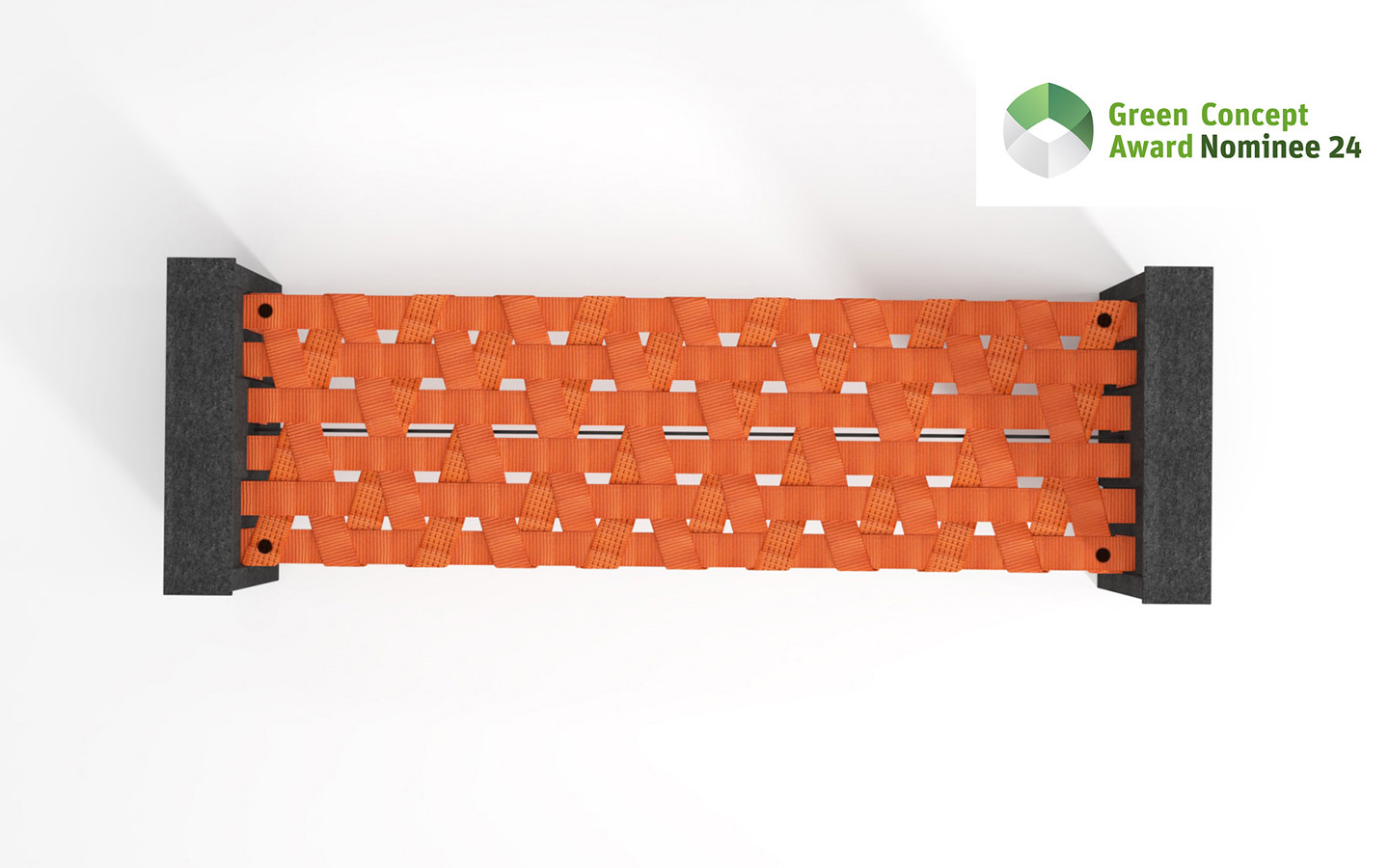

Re-Lax

The modular urban furniture from waste material

The Re-Lax project is a good example of material life extension. Products are made from two types of discarded plastics sourced from two different companies. Strong polyester belts for seat surface come from the port of Luka Koper, where they throw away 22t per year. The second polyester material is the felt. Up to 1800t per year is discarded and sent to an incineration plant. Through the technological process of thermoforming, felt is remanufactured into a main stiff construction part - the profiled panel. Urban furniture is modular and designed for disassembly. Each part is replaceable.

Company/Institution

Academy of Fine Arts and Design, University of Ljubljana

Country

Slovenia

Designer(s)

Barbara Prinčič

Slovenian designer Barbara Prinčič became well acquainted with environmental issues in design during her post-graduate studies in Holland. There, she quickly came to realise that this emerging field would serve as the main subject-direction of her career. Today, when environmental issues have made it to the forefront of the international agenda, she asserts that her time has come. She is an active promotor of material and product reuse, accomplishing this through her own design projects or together with the younger generations at the Academy of Fine Arts and Design in Ljubljana, Slovenia.